Applications

We manufacture plastic lumber for many industries in Canada and the USA.

Artificial Turf Nailers ●

Concrete Forming / Shoring ●

Landscaping ●

Site Furnishings ●

Decking ●

Scaffolding Beam Inserts ●

Fencing ●

Garden Beds & Edging ●

Skids / Pallets ●

Animal Barn / Pen ●

Refrigerator Door Panel ●

Trailer Decking ●

Ground-Contact / Marine Use ●

Artificial Turf Nailers ● Concrete Forming / Shoring ● Landscaping ● Site Furnishings ● Decking ● Scaffolding Beam Inserts ● Fencing ● Garden Beds & Edging ● Skids / Pallets ● Animal Barn / Pen ● Refrigerator Door Panel ● Trailer Decking ● Ground-Contact / Marine Use ●

Site Furnishing

Park Benches & Picnic Tables

Waste and Recycling Receptacles

Outdoor Signage and Trail Markers

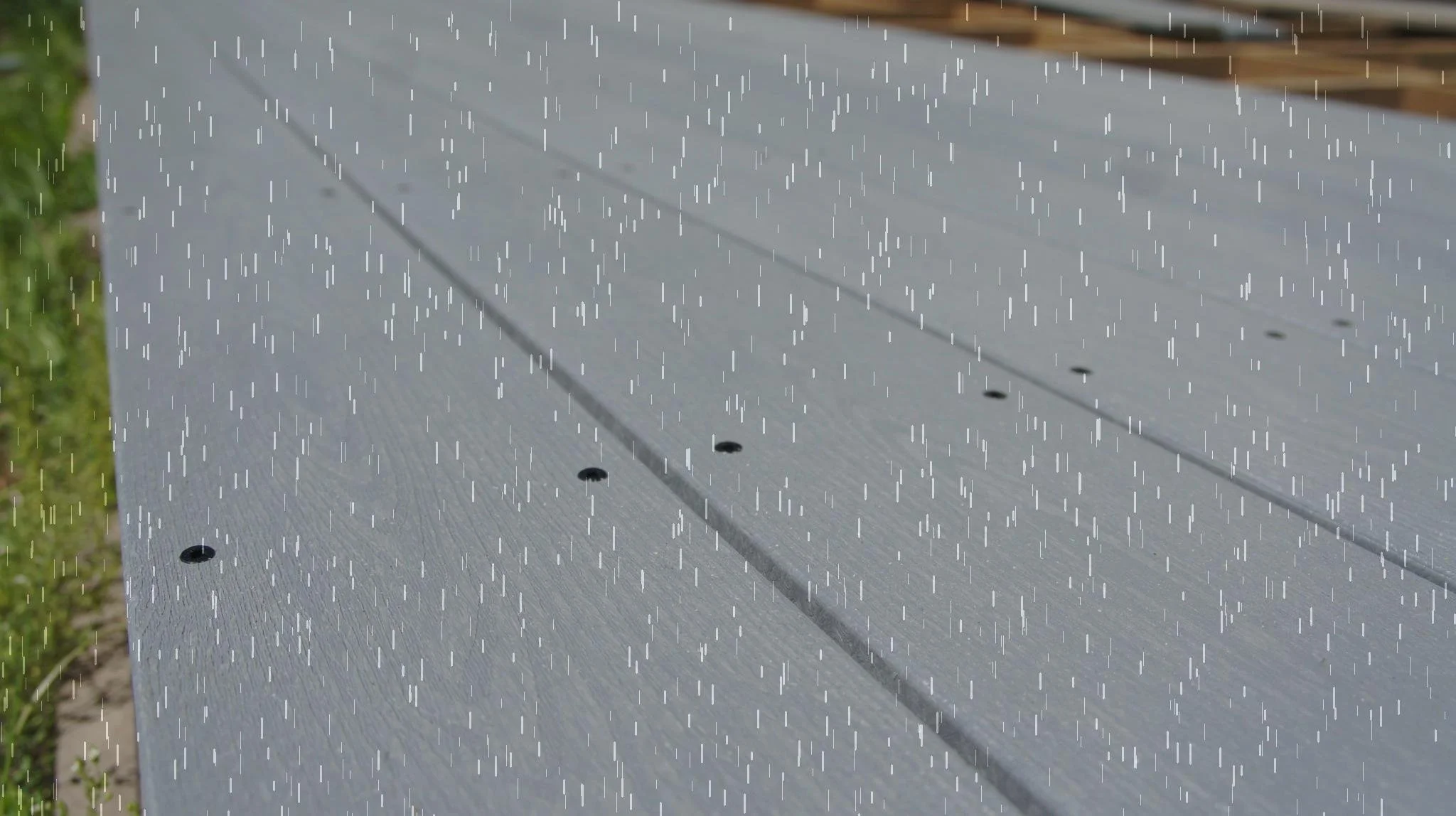

Decking

Backyard, Rooftop, Patio, and Balcony Decks

Cottage & Waterfront Docks

Boardwalks & Trails

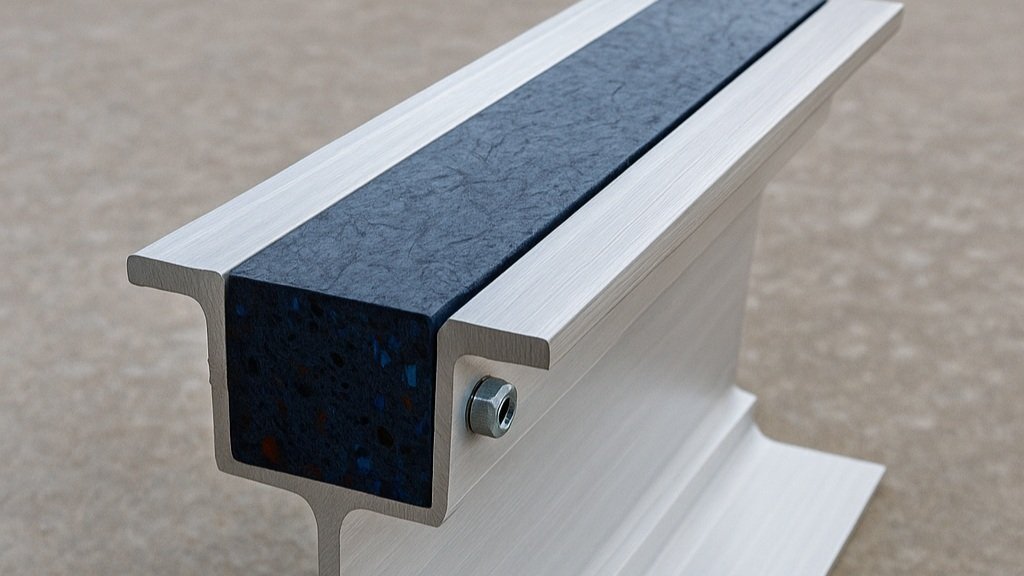

Nailer Board

Aluminum Beam Inserts for Scaffolding

Nailer Board for Artificial Turf Installation

Concrete Forming

Slab Edge and Footing Forms

Wall Form Blocking & Spreaders

Landscaping

Garden Beds & Edging

Retaining Walls

Tree Protectors

Agricultural

Livestock Enclosures & Fencing

Chew-Resistant Horse Stables

Shipping / Freight

Skids and Pallets

Truck and Trailer Bed Decking

Advantages

Durability

Plastic lumber is durable because it resists rot, moisture, insects, and chemical damage.

Made from high-density polyethylene (HDPE), it doesn’t splinter, warp, or crack, and its UV resistance helps prevent fading and degradation from sun exposure, ensuring long-lasting performance in harsh environments.

Sustainability

Plastic lumber is sustainable because it is made from recycled high-density polyethylene (HDPE), diverting plastic waste from landfills and reducing the demand for virgin materials.

The displacement of traditional wood also reduces the need for deforestation. It also has a long lifespan, and requires less replacement, reducing overall material and energy output.

FAQs

-

Plastic lumber is made entirely from HDPE plastic, making it completely moisture-resistant and highly durable. Composite lumber, on the other hand, contains wood fibers mixed with plastic, which can still absorb some moisture and may be more prone to mold or swelling over time.

-

Thermal expansion and contraction are natural phenomena that affect all materials. Recycled plastic lumber will experience predictable changes in size due to temperature fluctuations. The important thing is to measure and understand these changes so they can be properly accounted for in the design and use of your final product. Our team is happy to discuss and advise!

-

No, plastic lumber is not rated for structural use.

-

Yes, plastic lumber is made from recycled plastic and is fully recyclable. They can be recycled again after their useful life. Studies show that products made from HDPE last more than 50 years.

-

No, our products are infused with Ultra-Violet (UV) stabilizers, which help maintain the color and integrity of the resin for years. However, long-term, intense UV exposure and heat cycles can impact the surface finish and color stability of polymer-based products, as is the case with most materials over time.